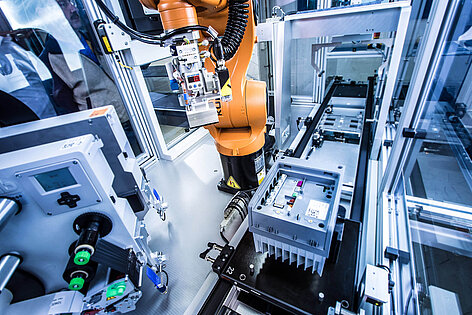

SOMA tests, secures and automates power electronics for e-mobility

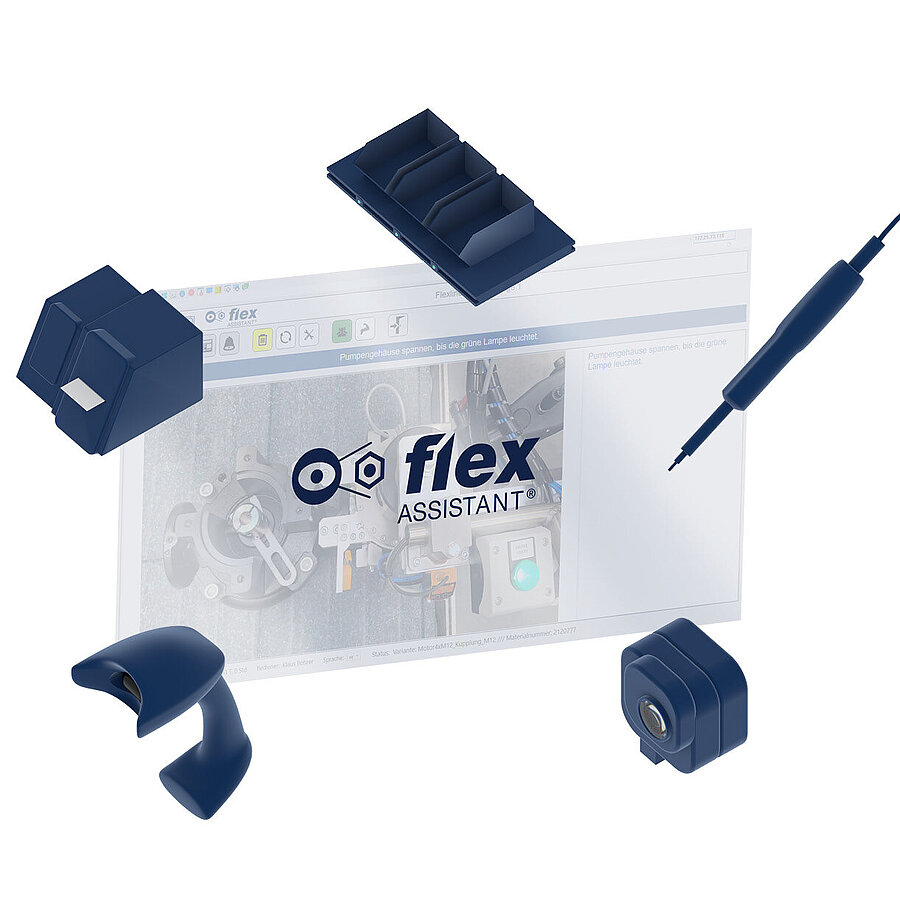

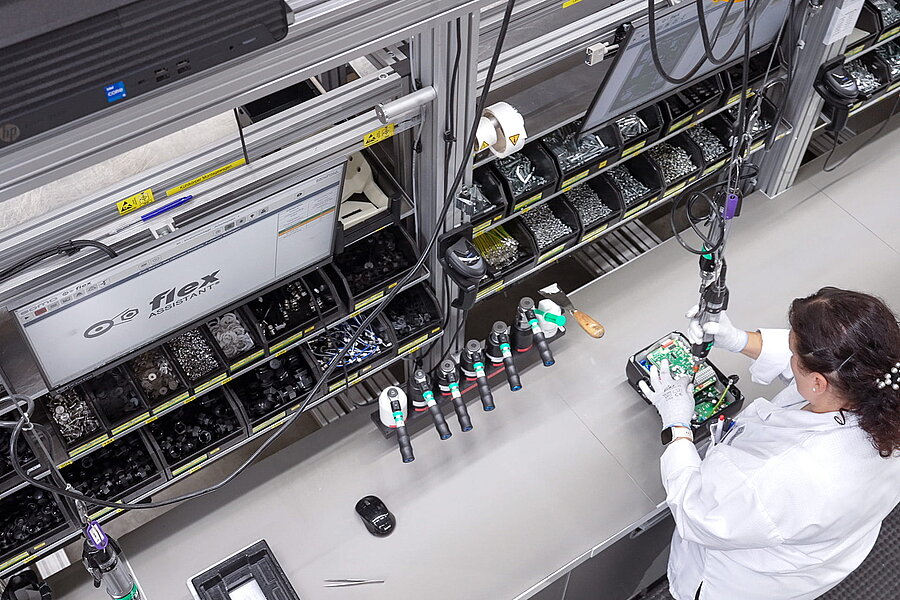

SOMA develops and implements testing and automation systems that enable control units, power converters and high-voltage components to be reliably tested, automatically manufactured and transferred to series production with consistently high quality.