![[Translate to English:] automatica](/fileadmin/_processed_/8/0/csm_soma-messe-automatica-grau_1876ca4719.jpg)

SOMA at automatica 2025 in Munich

From June 24 to 27, 2025, the "automatica" will take place in Munich. All information about the trade fair and the SOMA booth.

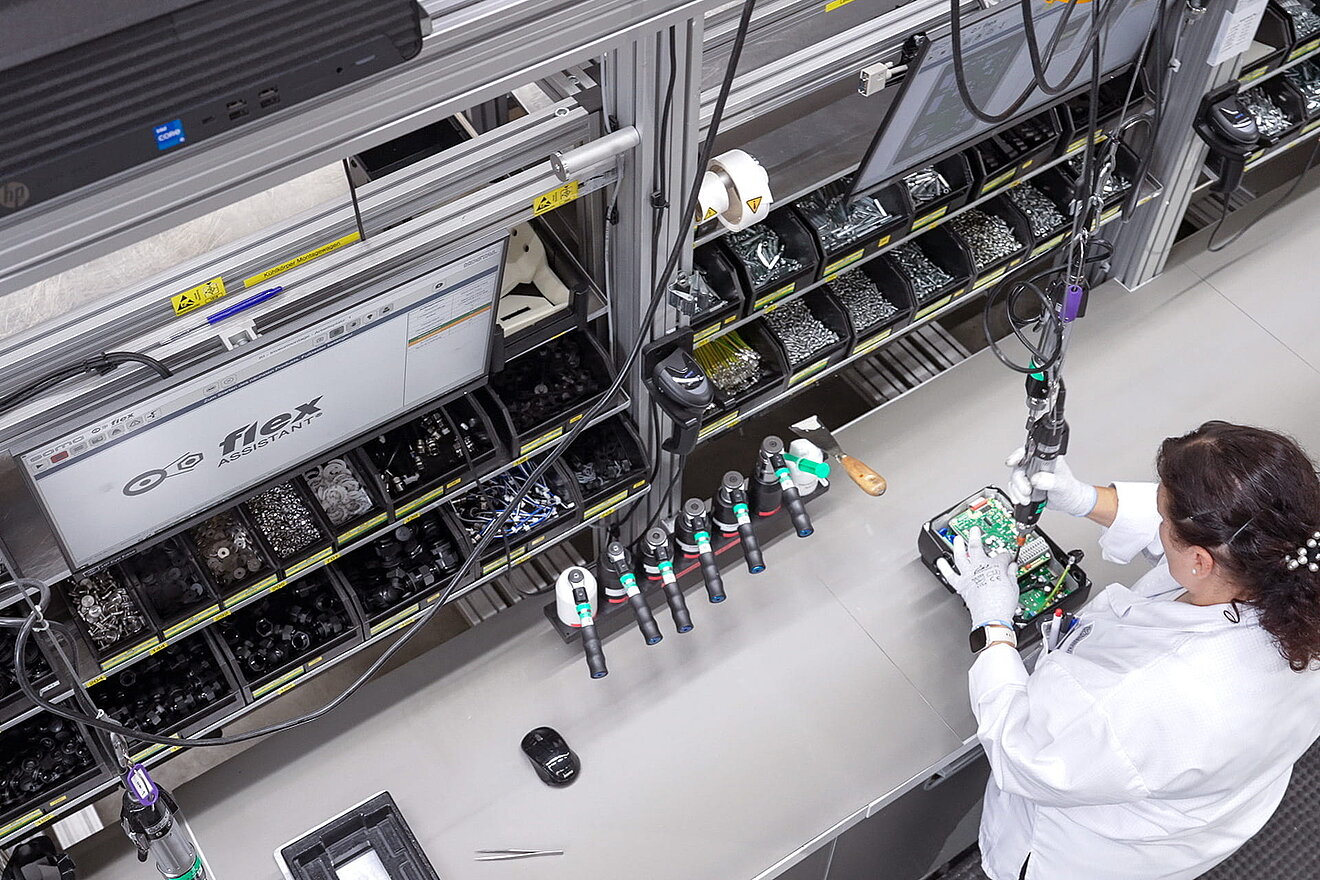

The advent of paperless manufacturing is transforming production processes. With worker assistance systems in manual assembly and manufacturing, employees can complete their tasks more efficiently and with fewer errors. flexAssistant provides real-time instructions and assistance directly at the workplace, eliminating the need for physical or paper documents.

Digitalisation has brought about a profound change in industry and increased the need for paperless manufacturing, production and assembly. Companies are faced with the challenge of optimising their manufacturing processes and replacing inefficient paper-based workflows with digital solutions. In numerous manufacturing companies, the transition to paperless manufacturing is seen as a pioneering step towards a digitalised future.

However, effective digital production requires much more than just scanning and electronically capturing documents. It involves providing information and data in real time directly at the assembly workplace, as well as the option of electronic feedback and documentation. The SOMA flexAssistant worker assistance system enables an efficient manufacturing process through digital work instructions.

Paperless manufacturing offers many advantages, enabling faster production and assembly, improved quality control and increased flexibility of business processes. Digital and paperless manufacturing enables companies to respond more effectively to customer requirements and increase their competitiveness.

By implementing paperless manufacturing methods, you increase efficiency through automated processes, benefit from reduced susceptibility to errors, better traceability of production data, lower operating costs and faster responsiveness to changing market requirements.

Holistic automation is crucial to the success of paperless manufacturing and production. Companies should not just digitise individual process steps, but digitally transform their entire manufacturing and assembly operations.

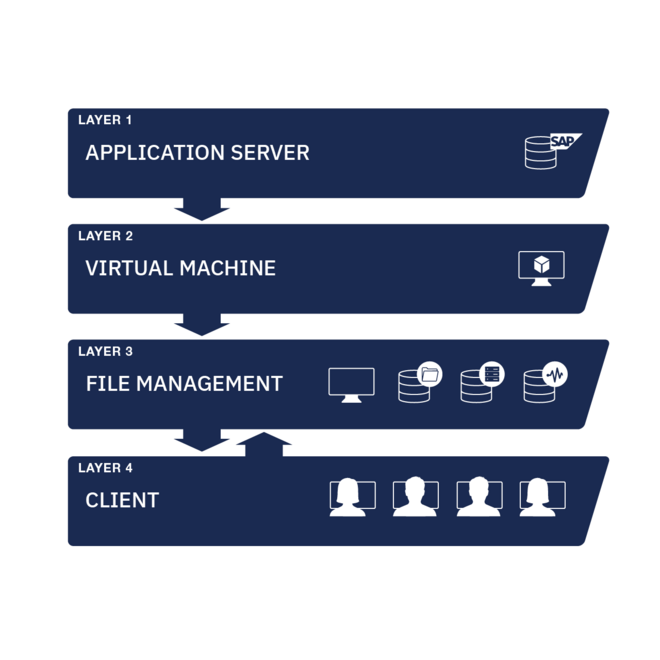

By connecting their ERP system, document management system and other digital components, companies can ensure efficient and transparent production, manufacturing and semi-automatic or manual assembly across different departments.

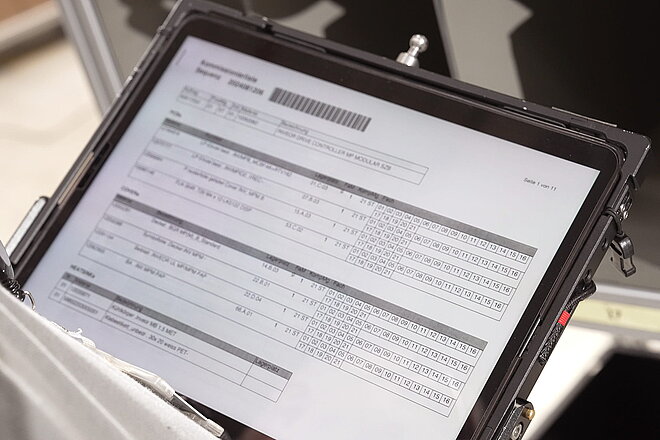

Eliminating the need to search for order-related documents can lead to increased efficiency in order processing. By digitising production documents and work instructions, employees can quickly and easily access the information they need, saving time and resources.

In addition, errors and delays can be minimised because the required documents are always up-to-date and easily accessible. Overall, paperless processes and digital instructions can increase the quality of work in the production process and contribute to improving employee motivation and satisfaction.

Do you have questions about our worker assistance system as an individual solution for your paperless manufacturing? We are happy to help. Please contact me.

Michael Penzel

Phone: +49 2355 50828-973

Email: m.penzel@soma.de

Conventional manufacturing methods based on paper-based processes often encounter a number of challenges and address a variety of issues in manufacturing and manual assembly. These include manual data entry, error-prone manufacturing processes and confusing checklists, longer lead times, limited transparency and traceability of production data, quality loss due to different document versions, and higher costs for paper document management and storage.

Paper-based manufacturing often results in long production times and inefficient workflows. Documents have to be distributed and processed manually, which can lead to delays and errors. By digitising documents and work instructions, companies can ensure that employees always have access to the latest information and avoid errors caused by outdated production documents. Paperless assembly enables faster information provision by replacing paper-based processes with digital ones.

How exactly does paperless assembly work with the SOMA flexAssistant worker assistance system? flexAssistant enables digitised assembly by providing workers with digital work instructions at the assembly workstation.

By using the SOMA worker assistance system, employees can work more efficiently because they no longer have to rely on paper instructions or manuals.

The flexAssistant system can also be integrated with other digital production and manufacturing systems (ERP, SAP, DMS, etc.) to ensure seamless communication and data exchange.

Using flexAssistant is extremely easy: employees start the worker assistance during their shift. After logging in, the employee receives the available work orders for the designated workstation from the work queue.

The next required order can be started by entering or scanning. flexAssistant automatically generates the work steps from the production order (e.g. from SAP) and a database.

A holistic approach is required for digital manufacturing, with a consistent transition to paperless solutions. The transition to paperless assembly and production usually occurs in stages. We analyse your paper-based processes as a starting point and define the project goal in collaboration with you.

Complex work processes in the assembly area due to a large scope of work, a high number of variants and complicated work instructions. This complexity has the following effects:

Introduction of a worker assistance system in production for the cognitive support of workers in the execution of their work with the following components:

The integration of the flexAssistant worker assistance system digitises assembly and work processes.

The new development or transition to paperless processes in assembly and production is carried out step by step. First, the system is developed, in which the digital infrastructure is designed and the necessary software for worker assistance is developed.

The next step is to create an operating concept that defines processes and procedures. To test the system in a test environment, a prototype is then built. This is followed by training for employees to prepare them for working with the new digital tools and assembly processes.

During commissioning, the system is finally integrated into the ongoing operation. Project management supports the entire changeover process to ensure that schedules and processes are adhered to, and to monitor and document implementation.

SAP offers a wide range of software solutions that are specifically tailored to the requirements of the manufacturing industry. These solutions include functions for planning, controlling and monitoring manufacturing processes, as well as for integrating business processes along the entire value chain.

SAP offers various software solutions that are specifically tailored to the requirements of the manufacturing industry. These include S/4HANA Manufacturing, Manufacturing Execution, Integrated Business Planning, Asset Intelligence Network, ERP and others.

The implementation of SAP solutions in paperless production requires careful planning and execution to ensure a smooth transition from traditional manufacturing processes to digital methods. The advantages of an SAP integration with flexAssistant are obvious:

The connection between the ERP system and the flexAssistant in production means efficient work and reduces errors in assembly. Thanks to the SOMA flexAssistant worker assistance and software suite, paperless production has become a reality in the KOSTAL Drives Technology business unit, for example.

Since the changeover and integration, manual assembly and production have been running smoothly, without delays caused by paper-based processes. Printed documents are no longer necessary because production is fully digitally controlled.

Would you like to learn how KOSTAL frequency converter assembly has been digitised and how you too can eliminate paper-based processes with the help of SOMA worker assistance? Let's get in touch and have a chat about it.

Do you have questions about our worker assistance system as an individual solution for your paperless manufacturing? We are happy to help. Please contact me.

Michael Penzel

Phone: +49 2355 50828-973

Email: m.penzel@soma.de

Digital methods and software are revolutionising Industry 4.0 and offering numerous advantages for companies on the road to the smart factory. Implementing modern strategies can optimise processes, make production processes more economical and increase productivity.

The digital transformation in Industry 4.0 enables real-time monitoring of production processes, highly automated data collection and seamless integration of various systems in manufacturing. Companies that implement paperless manufacturing benefit from reduced paper consumption, improved quality control and faster decision-making based on real-time data. By providing digital work instructions and checklists, manufacturing documents are always up to date and do not delay the assembly process due to missing paper documents.

The advantages of paperless production through the use of software solutions such as the flexAssistant worker suite lead to a competitive advantage, as companies can react more agilely and responsively to market demands. Through the intelligent linking of machines and processes, production becomes more profitable and flexible. The digital factory also offers the possibility of saving resources and reducing environmental impacts, which brings both ecological and economic advantages.

The SOMA flexAssistant worker assistance system is an industry-independent solution for your manual or semi-automated assembly. Real-time process monitoring and data exchange with your ERP, pick-by-light or pick-to-light system at the workstation and digital work instructions make the worker assistance system a flexible all-rounder for your company.

Find out how flexAssistant can help your company to successfully digitise paper-based processes, reducing your environmental impact, improving employee satisfaction and increasing the profitability of your production.

Do you have questions about our worker assistance system as an individual solution for your paperless manufacturing? We are happy to help. Please contact me.

Michael Penzel

Phone: +49 2355 50828-973

Email: m.penzel@soma.de

SOMA has received the TOP 100 award for the second time in a row. This prize is awarded annually to top innovators among Germany's SME sector.

![[Translate to English:] automatica](/fileadmin/_processed_/8/0/csm_soma-messe-automatica-grau_1876ca4719.jpg)

From June 24 to 27, 2025, the "automatica" will take place in Munich. All information about the trade fair and the SOMA booth.

From June 3 to 4, 2025, the "all about automation" will take place in Hamburg. All information about the trade fair and the SOMA booth.

SOMA GmbH has once again won through in the Top 100 innovation competition and will now bear the Top 100 2025 seal of quality, which is only awarded…